ProTec | Qualität

Wir sind seit 25 Jahren ein zuverlässiger Systemlieferant der Automobilindustrie.

Quality first

Qualitätssicherung

Unsere Qualitätssicherung ist ein essentieller Bestandteil unseres Unternehmens, der sicherstellt, dass unsere Produkte den hohen Qualitätsstandards unserer Kunden entsprechen.

Sie umfasst eine Reihe von Maßnahmen und Prozessen, die darauf abzielen, Fehler zu minimieren und die Kundenzufriedenheit zu maximieren.

Um dieses Ziel zu erreichen sind verschiedene Schritte notwendig.

Zunächst einmal müssen klare Qualitätsstandards definiert werden.

Diese stellen wir für alle unsere Mitarbeiter transparent dar und aktualisieren sie regelmäßig, um den aktuellen Anforderungen gerecht zu werden.

Des Weiteren sind Kontrollmaßnahmen erforderlich, um sicherzustellen, dass diese Standards eingehalten werden. Dies stellen wir durch interne Audits und auch externe Zertifizierungsverfahren sicher. Dabei überprüfen wir, ob alle Prozesse korrekt durchgeführt werden und ob eventuelle Abweichungen behoben wurden

Qualitätsmanagement

Qualitätsmanagement in der Automobilindustrie spielt eine entscheidende Rolle, um sicherzustellen, dass Fahrzeuge den höchsten Standards und Anforderungen gerecht werden.

In einer Branche, die für ihre technische Präzision und Sicherheit bekannt ist, ist es von größter Bedeutung, dass jedes einzelne Bauteil eines Autos fehlerfrei funktioniert.

Qualitätssicherung

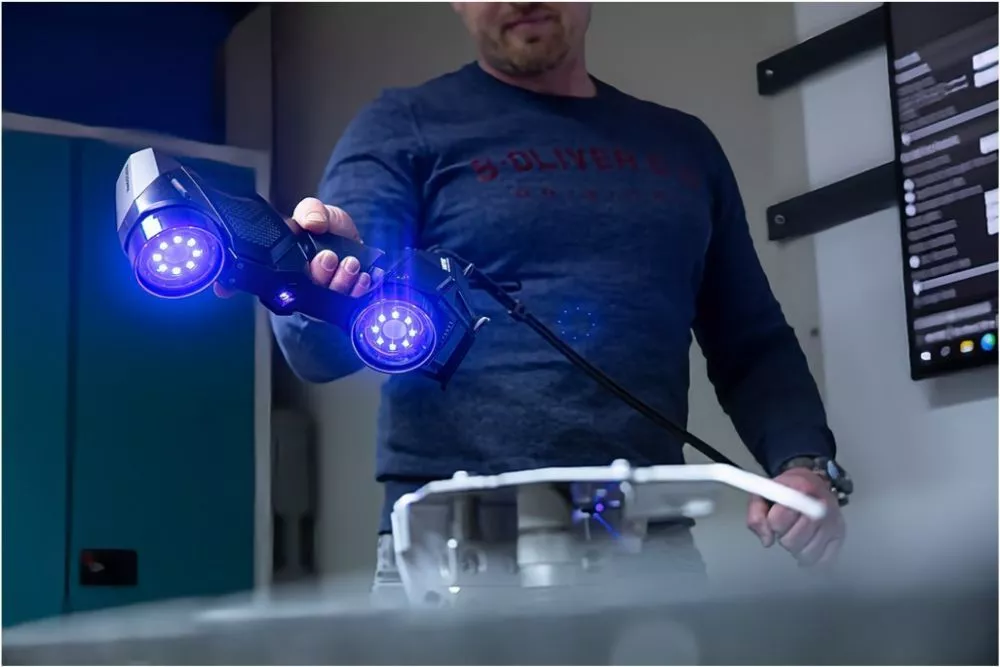

optische Messverfahren

Optische Messgeräte bieten im Vergleich zu taktilen Messgeräten einen entscheidenden Vorteil: Die Bauteile können direkt auf dem Messtisch gemessen werden, ohne dass sie ausgerichtet werden müssen. Darüber hinaus sind optische Messungen schneller als taktile Messungen und führen nicht zur Verformung der Bauteile. Zudem ermöglichen sie die Durchführung von Messungen, bei denen der Messtaster eines taktilen Geräts zu groß wäre. Mit unserer Modellreihe LM von KEYENCE können wir per Knopfdruck bis zu 100 Bauteile messen - einfach und effizient.

Qualitätssicherung

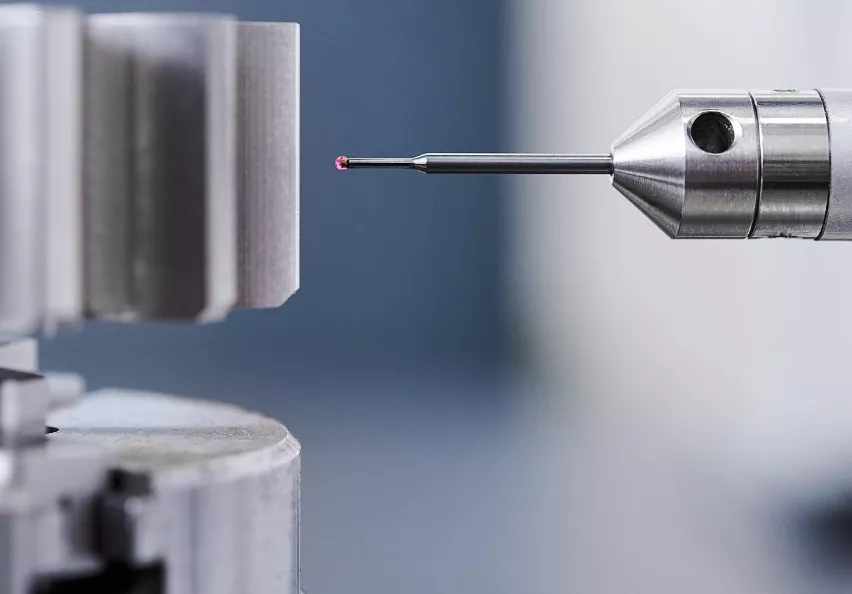

Taktile Messverfahren

Durch den Einsatz von taktilen Messgeräten können wir verschiedene Parameter wie Oberflächengüte, Maße oder Formabweichungen. messen. Diese Informationen sind für uns äußerst wichtig, da sie uns dabei helfen, mögliche Fehler oder Unregelmäßig-keiten frühzeitig zu erkennen und entsprechende Korrekturmaßnahmen einzuleiten.

Qualitätssicherung

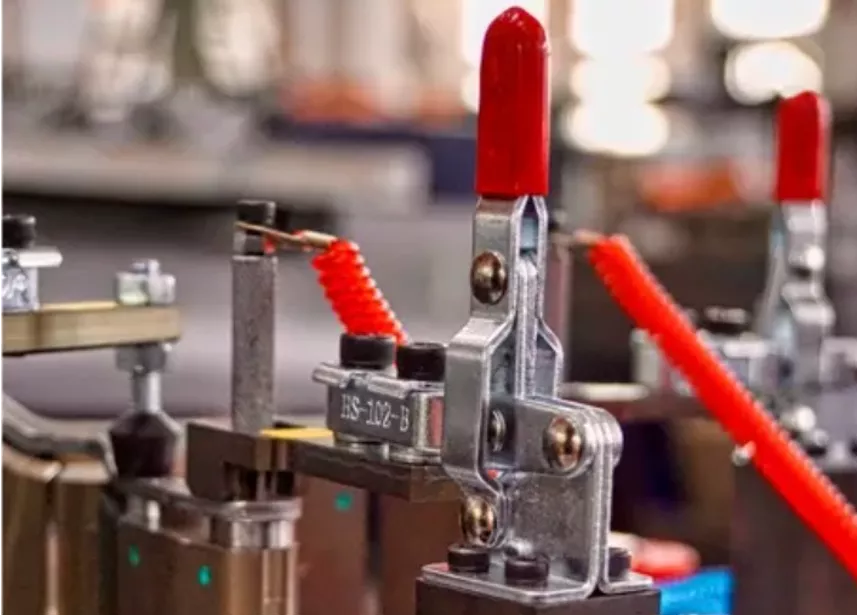

Prüflehren

Um eine gleichbleibend hohe Qualität in der Serienproduktion sicherzustellen, setzen wir Prüf- und Messlehren ein. Sie ermöglichen eine schnelle optische und maßliche Kontrolle unserer Bauteile und Komponenten. Wir nutzen sowohl Kunststoff- als auch Metallprüf-und Messlehren. Dabei werden alle relevanten Parameter individuell auf den jeweiligen Produktionsprozess abge-stimmt.

Qualitätssicherung

Werker Selbstkontrollen

Unsere Werker- Selbstkontrolle hilft dabei, die Qualität unserer Produkte sicherzustellen. Dabei werden von unseren Mitarbeitern-innen die Bauteile und Baugruppen, selbstständig geprüft, um sicherzustellen, dass sie den Qualitätsstandards unserer Kunden entsprechen. Dieser Prüfprozess erfolgt entlang des Materialflusses vor der Endkontrolle, durch einen Qualitäts-prüfer. Dadurch wird die Anzahl an Fehlern reduziert und eine hohe Produktqualität gewährleistet. Die Ergebnisse dieser Selbstprüfung werden anschließend analysiert und mit dem angestrebten Zustand verglichen. Bei Abweichungen leiten wir Verbesserungs-maßnahmen in den Prozessen ein.

DIN EN ISO 14001:2015

ProTec Metalltechnik GmbH |

Spreestraße 19 |

82538 Geretsried |

Tel.: +49(0)8171 9333-0 |

Fax: +49(0)8171 9333-30 |

info@protec-metall.com |

www.protec-metall.com |