ProTec | Konstruktion

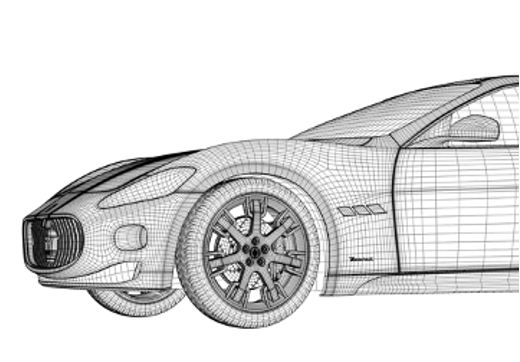

Wir sind seit 25 Jahren ein zuverlässiger Systemlieferant der Automobilindustrie.

CAD Werkzeugkonstruktion

Unser Prozess zur Konstruktion von Stanz- und Umformwerkzeugen bei ProTec Metalltechnik

Als Spezialisten für die Konstruktion von Stanz- und Umformwerkzeugen verstehen wir, dass jeder Schritt im Entwicklungsvorgang entscheidend für die Endqualität Ihres Produkts ist. Unsere erfahrenen Ingenieure und Techniker kombinieren Fachwissen mit modernster Technologie und bilden somit das Fundament für den Erfolg Ihres Projekts.

Und so funktioniert unser Prozess:

1. Machbarkeitsanalyse mit Simulation

Bevor wir das eigentliche Design und die Konstruktion Ihrer Werkzeuge angehen, beginnt unser Prozess mit einer gründlichen Machbarkeitsanalyse. Wir nutzen fortschrittliche Simulationssoftware, um Ihre Designkonzepte zu überprüfen und zu optimieren. Durch die Simulation verschiedener Szenarien können wir Materialverhalten vorhersagen, Formänderungen analysieren und potenzielle Fehlerquellen bereits im Vorfeld identifizieren. Dieser Schritt ist essentiell, um Materialverschwendung zu minimieren und die Durchlaufzeit zu optimieren.

2. Methodenplanung

In der Methodenplanung definieren wir den optimalen Herstellungsprozess. Dabei untersuchen wir, welche Arbeitsschritte nötig sind, und in welcher Reihenfolge diese für das beste Ergebnis durchgeführt werden sollten. Die Planung umfasst auch die Auswahl geeigneter Maschinen und Materialien, um eine hohe Prozesssicherheit und Wirtschaftlichkeit sicherzustellen. Mit der Erstellung detaillierter Arbeitspläne wird eine transparente und reibungslose Produktion ermöglicht.

3. Konstruktion

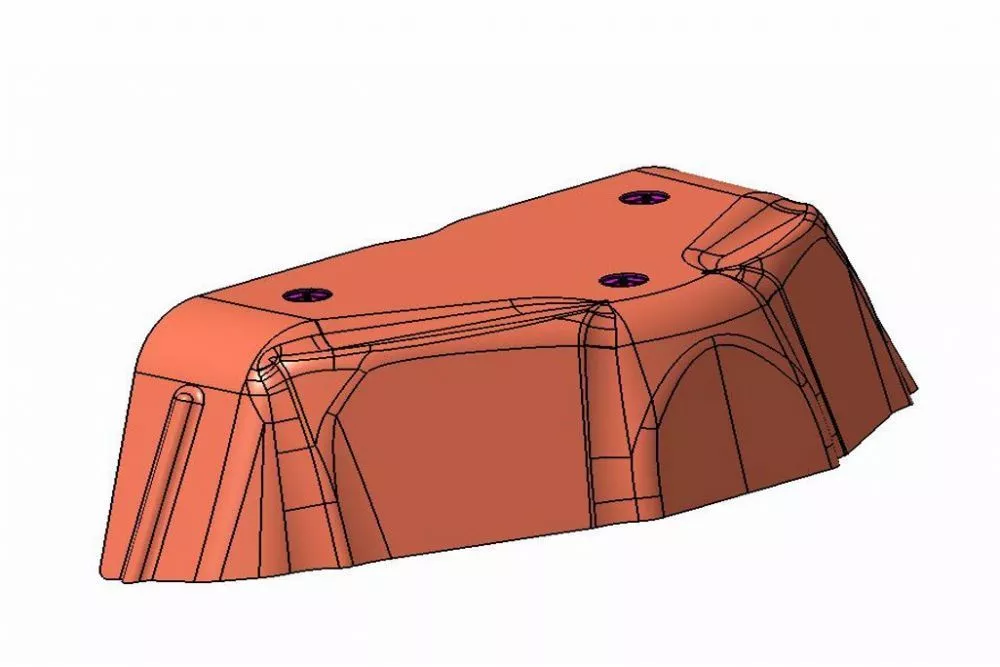

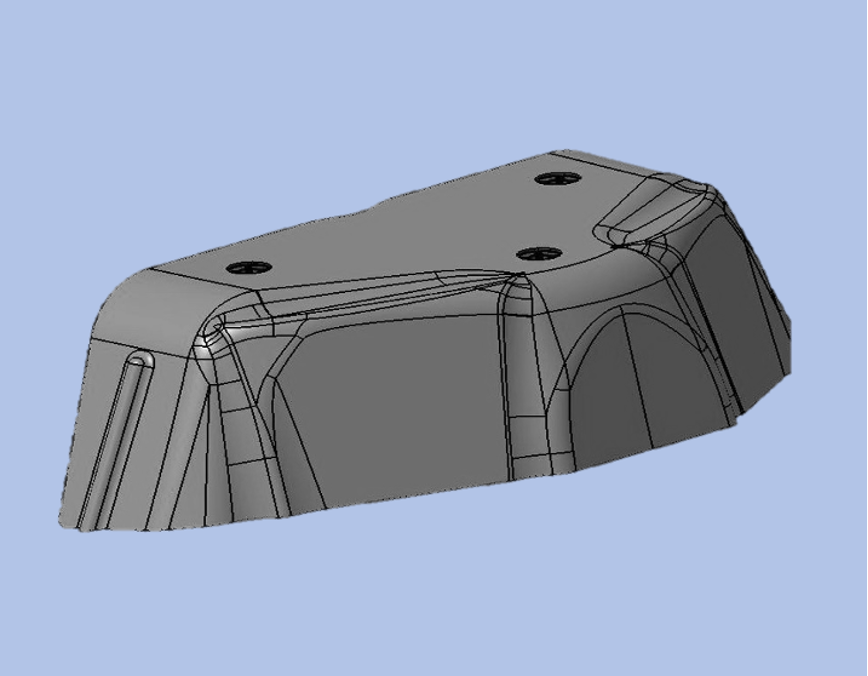

Die eigentliche Konstruktion der Stanz- und Umformwerkzeuge stellt das Herzstück unserer Arbeit dar. Mit Hilfe modernster CAD-Systeme entstehen präzise und detailgenaue 3D-Modelle Ihrer Werkzeuge. Unsere Konstrukteure betrachten jedes Projekt als einzigartig und entwickeln die Werkzeuge maßgeschneidert auf Ihre Anforderungen. Dafür berücksichtigen sie nicht nur die gewünschte Funktion und Form des Endproduktes, sondern auch Aspekte wie Fertigungszeit, Kosten und Langlebigkeit des Werkzeugs.

Der gesamte Prozess der Konstruktion von Stanz- und Umformwerkzeugen bei ProTec Metalltechnik ist von Präzision und Qualität geprägt. Wir streben danach, Ihnen nicht nur Produkte, sondern echte Lösungen anzubieten – und das von der ersten Idee bis zum fertigen Werkzeug. Unsere umfassende Expertise und die Symbiose von traditionellem Handwerk und zukunftsorientierter Technologie ermöglichen es uns, Werkzeuge von herausragender Qualität und Leistungsfähigkeit zu konstruieren. Treten Sie in Kontakt mit ProTec Metalltechnik, um mehr über unsere Dienstleistungen zu erfahren und das Potenzial Ihrer Projekte voll auszuschöpfen.

Machbarkeitsanalysen

Im Rahmen einer Machbarkeitsanalyse überprüfen wir zunächst mögliche Lösungsansätze hinsichtlich ihrer technischen Umsetzbarkeit sowie der Stabilität und Zuverlässigkeit des Herstellungsprozesses. Dabei analysieren wir die verschiedenen Ansätze, identifizieren Risiken und schätzen alternative Möglichkeiten ab. Sollten dabei Grenzen der Physik erreicht werden, entwickeln wir gemeinsam mit Ihnen potenzielle Lösungswege.

Um alternative Konzeptmethoden schnell zu bewerten, nutzen wir modernste Softwarelösungen. Mit dieser Software können wir komplette Prozesse von Tiefziehwerkzeug über Trimmmesser bis hin zu Fertigungs- und Nachformwerkzeug simulieren.

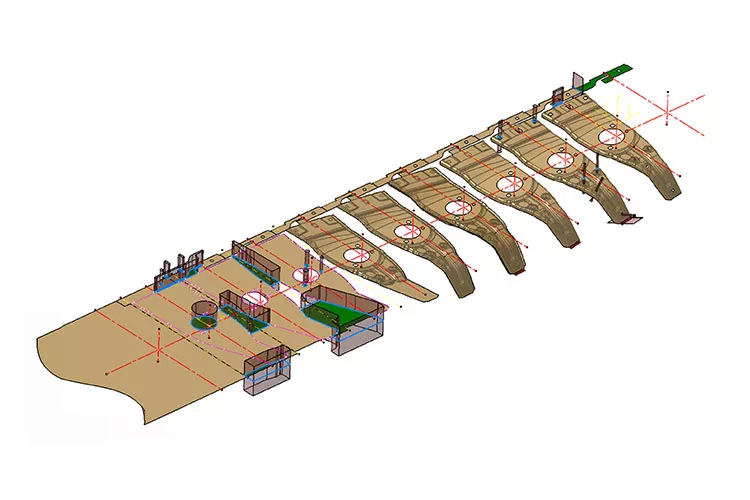

Methodenplanung

Innerhalb unserer Planungsmethoden legen wir detailliert den Ablauf des Produktionsprozesses Schritt für Schritt fest.

Dabei bestimmen wir die Werkzeuge, die Reihenfolge der Operationen und letztendlich das fertige Bauteil.

Wir legen großen Wert auf eine wirtschaftliche Produktion unter Berücksichtigung des Materials, der Anzahl und Art der Pressmaschinen sowie ihrer Hubgeschwindigkeit und geplantem Stückausstoß.

Um alternative Konzeptmethoden schnell zu bewerten, nutzen wir modernste Softwarelösungen. Mit dieser Software können wir komplette Prozesse von Tiefziehwerkzeug über Trimmmesser bis hin zu Fertigungs- und Nachformwerkzeug simulieren.

Konstruktion

Mit unserem erfahrenen Team von Konstrukteuren sind wir in der Lage, jede Aufgabe präzise und auf höchstem Qualitätsniveau zu bewältigen - sei es für Folgeverbund-, Transfer- oder Einzelwerkzeuge.

Wir setzen konsequent auf eine fertigungsgerechte Konstruktion, um eine Steigerung der Qualität im gesamten Produktionsprozess sicherzustellen.

Während des gesamten Konstruktionsprozesses arbeiten wir eng mit unseren Kunden zusammen, um eine hohe Transparenz zu gewährleisten.

Um die Werkzeugkonstruktionen zu validieren, simulieren wir die Abläufe und erkennen mögliche Probleme frühzeitig - noch bevor sie tatsächlich erprobt werden müssen. Dadurch können diese Probleme bereits im Vorfeld behoben werden.

ProTec Metalltechnik GmbH |

Spreestraße 19 |

82538 Geretsried |

Tel.: +49(0)8171 9333-0 |

Fax: +49(0)8171 9333-30 |

info@protec-metall.com |

www.protec-metall.com |